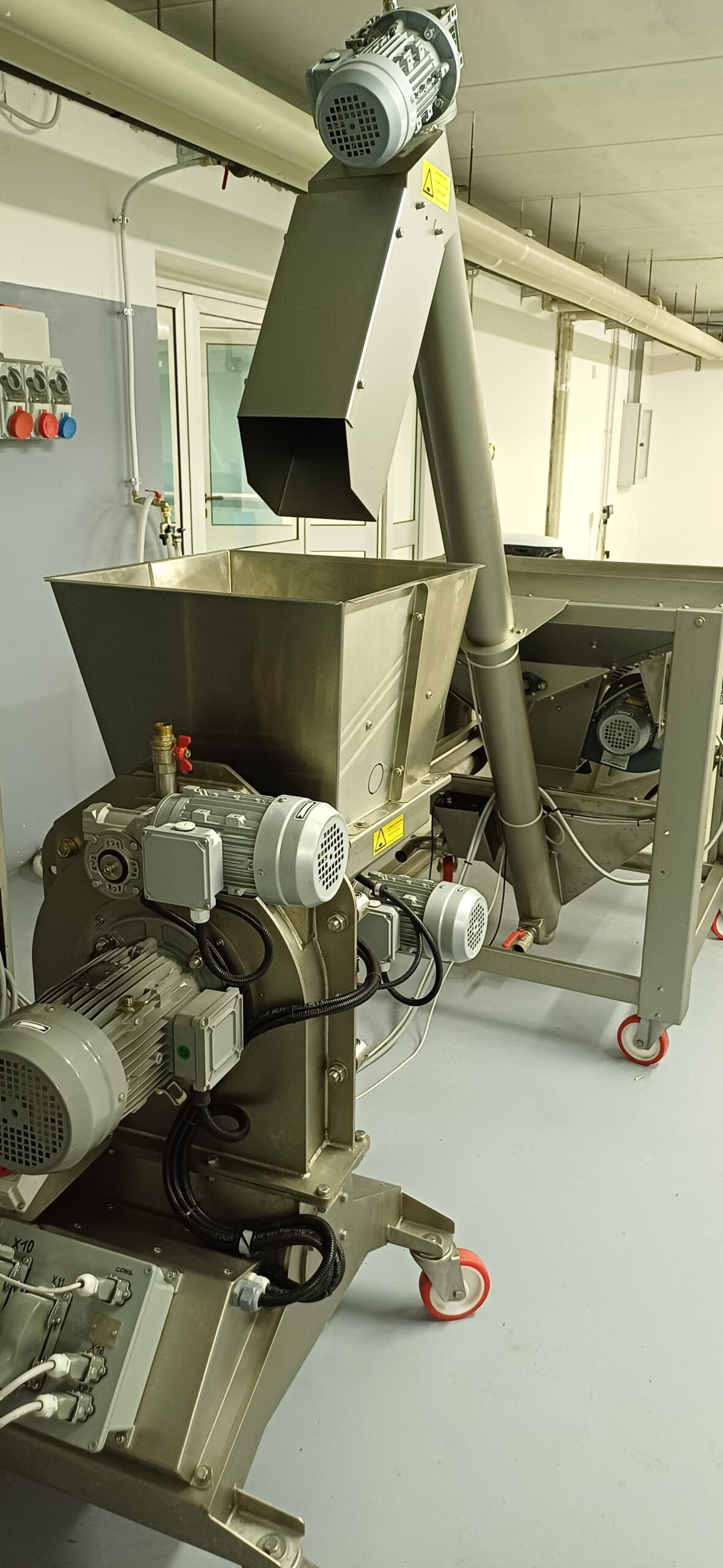

Crusher

The experimental oil mill is engaged in processing small quantities of olives, paying special attention to the enhancement of local cultivars and optimization of extraction processes. The olives are processed into extra virgin oil using innovative methods. Once the oil is obtained, samples are taken for analysis in in-house laboratories, where chemical-physical characterization and sensory analysis are carried out. These activities provide valuable information not only on the quality of the oil produced, but also on how to improve extraction techniques and enhance the olive varieties used, thus contributing to research and development in the olive oil sector.

The system was designed with the goal of supporting specific experiments and allows for the adjustment of numerous parameters during the olive oil production cycle. Because of this flexibility, it is possible to modulate crucial factors such as temperature, presence of oxygen, use of ultrasound, and machine speed according to our intended research objectives. This allows for more in-depth investigations and highly targeted research results.

Features of the Laboratory

In theolive oil production process, the olive mill is a crucial element, equipped with various equipment designed to ensure high-quality extraction and preserve the organoleptic characteristics of the oil. Each tool has a specific role, contributing synergistically to the entire production cycle. The main equipment includes:

COLD CELL

A fundamental tool for preserving olives, as it helps to preserve their quality. Thanks to controlled temperatures, this device slows down the degradation of olives over time, preventing unwanted processes from compromising the quality of the oil produced.

ULTRASOUND GENERATOR

Innovative device used to increase the extraction of aromatic and phenolic substances in oil. Ultrasonic waves generate vibrations that facilitate the extraction of various characteristic compounds, enriching the sensory profile of oils. Thanks to this instrument, it is possible to innovate and improve traditional methods of oil extraction.

DEFOGLIATION AND WASHING GROUP

Apparatus that deals with the removal of leaves and impurities from olives. Using clean water and a ventilation system, it ensures that only well-cleaned fruits continue in the production cycle. Thorough defoliation and effective washing are crucial to prevent contamination that could alter the organoleptic profile of the oil.

TURBOEMULSER DCM 5L (REACTOR)

Innovative tool designed for the production of high-quality emulsions, capable of working with liquid, creamy and pasty products. Thanks to its advanced technology, it ensures perfectly blended and homogenized slurries, making it ideal for creating a wide range of formulations. It is perfect for both cosmetic and chemical applications.

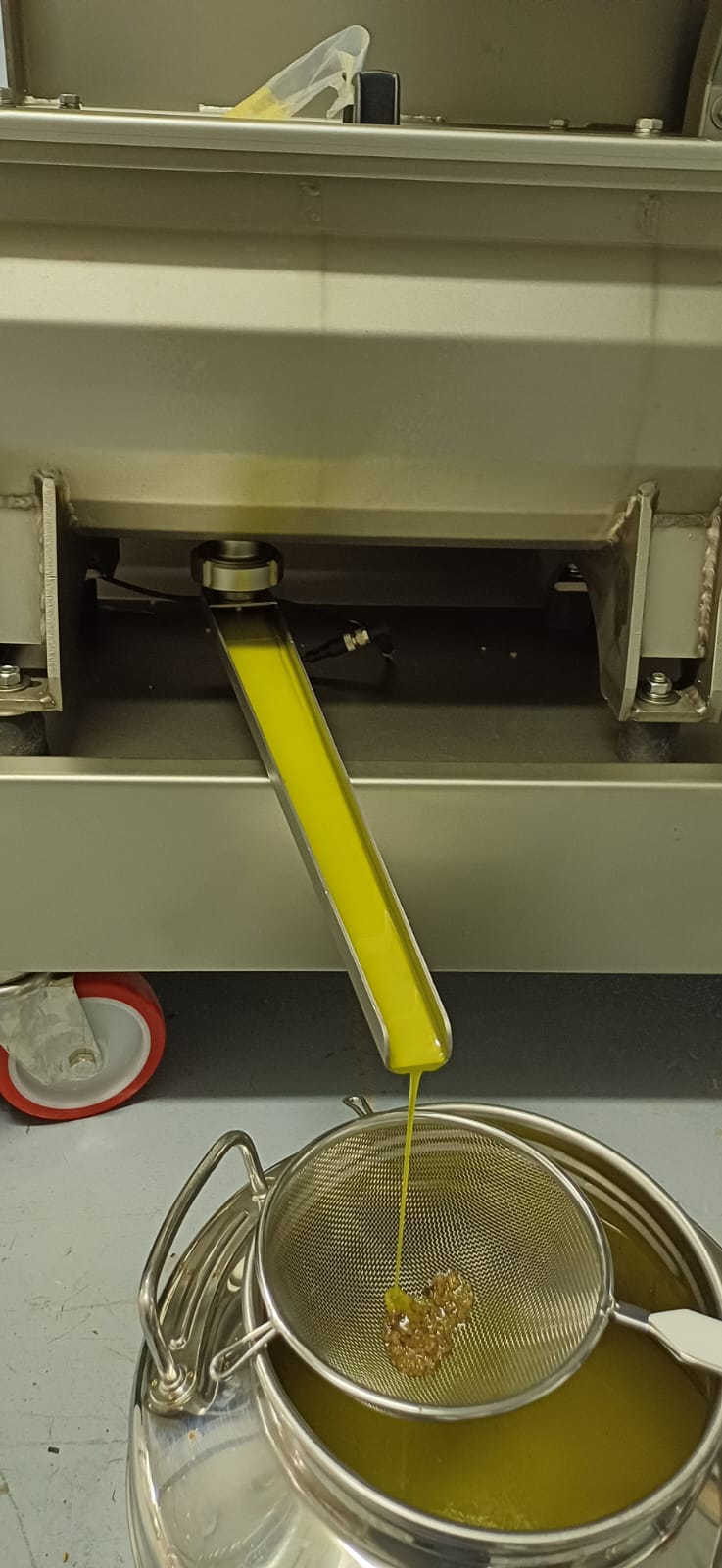

EXPERIMENTAL MINI-FRACTURE

Instrument designed for processing small quantities of olives, with a capacity of 30-40 kg per hour. Ideal for immediate post-harvest processing, it enables optimization of extra virgin oil production. Due to its versatility, it allows for experimentation with production variables such as crushing speed, crushing times and temperatures, offering advanced control over the production process.

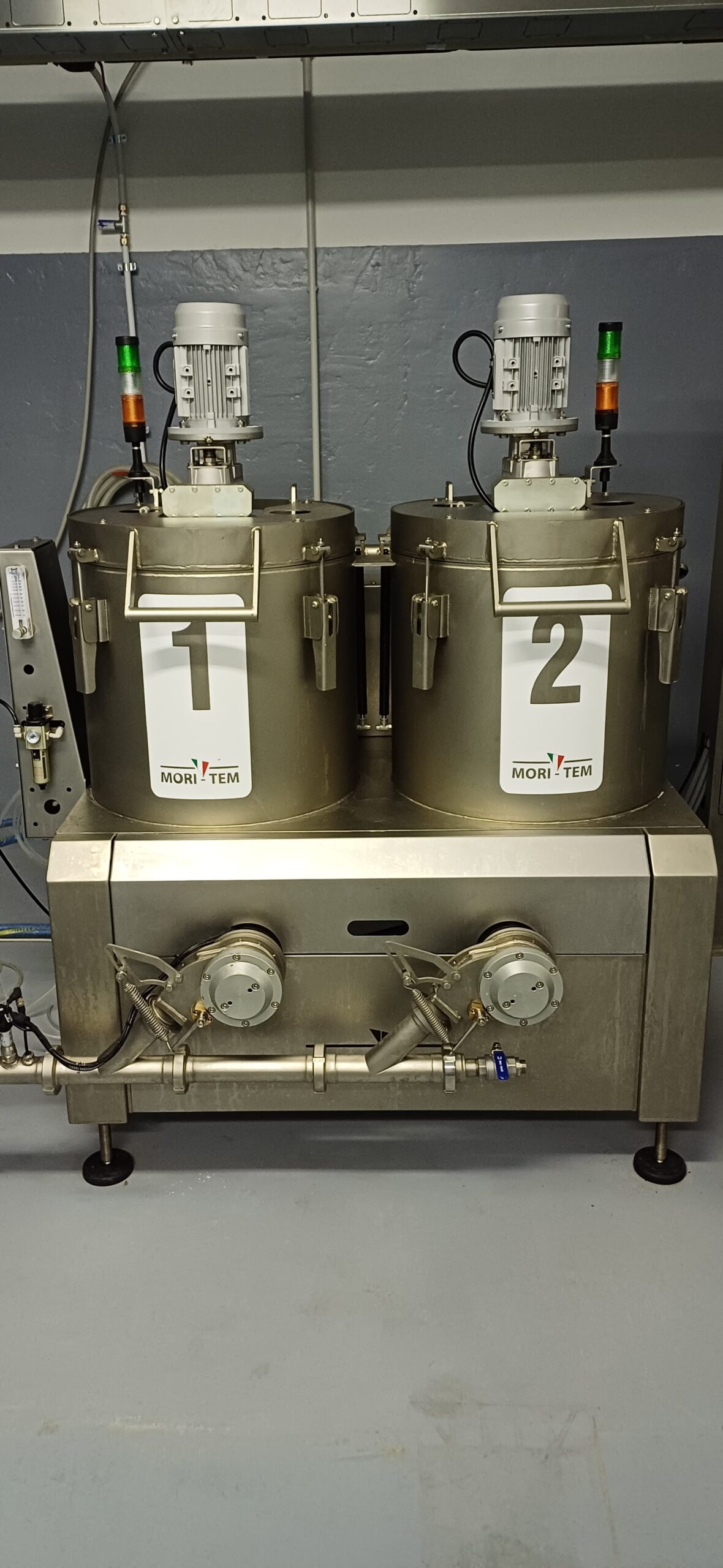

GRAMOLE GROUP

Equipment that allows efficient mixing of the olive paste obtained at the crushing stage. The cavity on the walls of the kneading units allows temperature control during kneading, a crucial element for the yield and organoleptic characteristics of the oil. If necessary, the process can take place in the absence of oxygen(vacuum), reducing oxidation and improving the preservation of aromatic and phenolic substances, thus contributing to a high-quality final product.

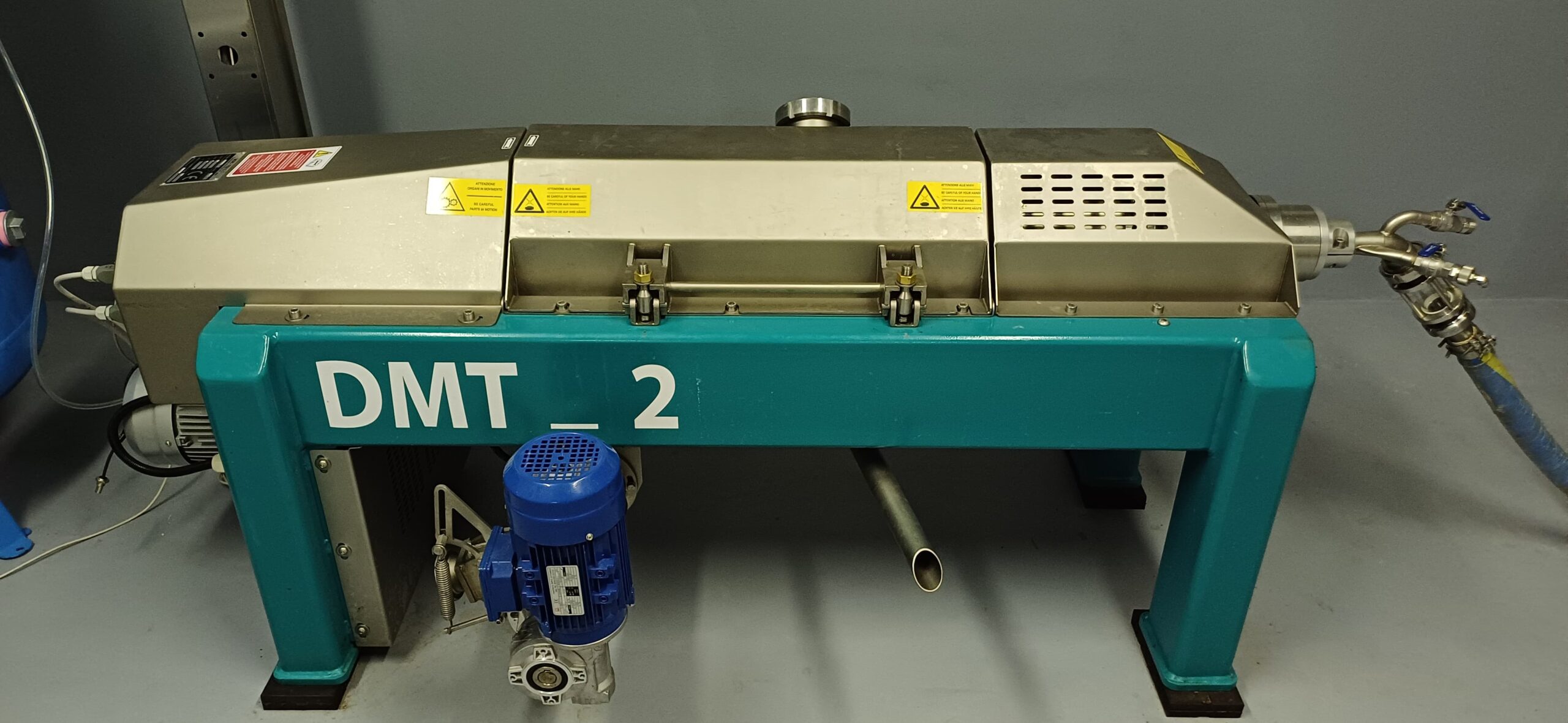

FRANGITOR

An instrument that carries out the crushing of olives, breaking down the pulp and allowing the oil to be released, thus creating the olive paste. The crusher used is of the “knife” type, which allows a balanced release of phenolic and aromatic substances, ensuring a more balanced oil than other types. It is also equipped with a crushing speed control, optimizing processing according to the variety of olives used. By changing the speed, it is possible to influence both the oil yield and its sensory characteristics, allowing a customized approach for each type of olive.